In our today's article we will talk about what types of timing belt are. It is useful for every car owner to know such basics, because they help a lot with self-repairing a car.

Content:

- Timing drive types

- What is a camshaft

- Timing types

- Gas distribution mechanism SOHC

- Gas distribution system DOHC

- Gas distribution system OHV

- Conclusion

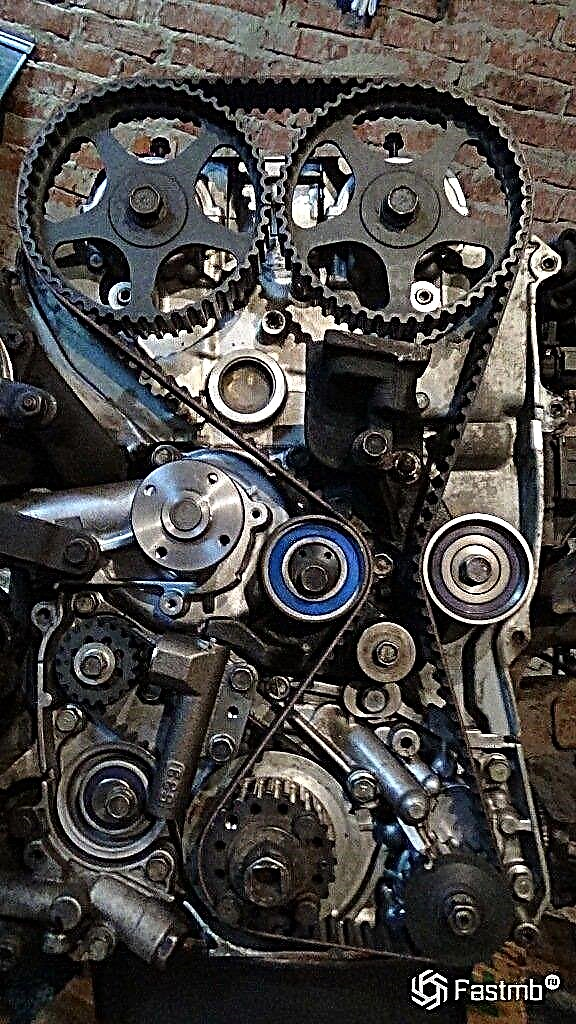

Each gas distribution mechanism is driven by a crankshaft. It can be made either in the form of a belt, or in the form of a gear from the crankshaft, or in the form of a chain. Each drive has its own disadvantages and advantages.

Timing drive types

There are three main types of drives, there are others, but they are not used on production vehicles:

- The belt is less noisy during operation, however, breaking it often leads to damage to the valves. Insufficient preload leads to skipping and phase displacement, respectively, to difficult starting, unstable idle, engine incomplete power, etc.

- The chain also has such a "sin", however, it has a tensioner that applies much more force than on the belt. Such a timing drive is reliable, but it is quite noisy, so automakers are trying to use it less and less.

- The crankshaft gears were used for a long time, in lower-shaft engines, that is, when the camshaft was directly in the cylinder block, and not in the head, we will talk about this in the next subsection.

What is a camshaft?

This shaft is needed so that at a certain moment the valves are opened, after which the working mixture enters the cylinder, and the exhaust gases come out. This is done thanks to the eccentrics on the shaft. It is rigidly connected to the crankshaft, so, for example, the intake valve only opens before the start of the intake stroke when the cylinder is at bottom dead center.

The camshaft can be located in the head of the block, such engines are called overhead shaft, no matter how many shafts are installed here. It can also be in the cylinder block, as mentioned above. This is called a bottom drive motor. In this case, the actuator is transmitted to the valve through the rods that pass through the entire motor to the block head. The main disadvantage of this mechanism is its slowness and great inertia. The lower-shaft engines spin quite hard, they have a high oil consumption, in contrast to the upper-shaft engines, where there are practically no drawbacks.

Timing types

It should be clarified right away that above we considered the types of the drive of the gas distribution mechanism, and not the mechanisms themselves. So, now let's look, for example, at the difference between DOHC and SOHC. So, let's begin.

Gas distribution mechanism SOHC

This name was not obtained by chance. This type was originally called simply OHC. This means Overhead Camshaft, which translates to "overhead camshaft". Later it was renamed SOHC after the first DOHC engine was designed, we'll talk about it later.

So, such an engine is distinguished by the installation of one camshaft in the cylinder head. The SOHC gas distribution system, contrary to common beliefs, can be equipped with either two or four valves per cylinder.

Let's see what are the positive points here and which are negative, there are not so many of them:

- The relative silence of the work. Unlike DOHC, there is only 1 shaft, which means the engine runs quieter, albeit only slightly.

- Relative simplicity. The same DOHC engine has 2 shafts, which complicates the design.

- One minus, perhaps, conditional. If the engine is equipped with two valves per cylinder, then the latter are less ventilated, which leads to a drop in power.

- And here's another drawback, which is definitely in all engines of this type. It consists in the fact that in an engine with 4 valves per cylinder, they are all driven by one camshaft. This makes it more fragile and subject to stress. In addition, the phase angle is reduced, which contributes to poorer filling and ventilation of the cylinders.

Gas distribution system DOHC

Such a mechanism looks almost the same as the one discussed above, however, it differs from it in the presence of a second camshaft. Thus, one shaft drives only the intake valves, and the other only drives the exhaust valves. Such a system also has its disadvantages and advantages, we will not dwell on them in more detail. Such a system was invented in the 80s of the last century and has not changed much during this time. So, the presence of a second camshaft significantly increases the cost, as well as complicates the design.

On the other hand, the DOHC gas distribution mechanism is characterized by lower fuel consumption, since the cylinders are better filled, and then almost all crankcase gases come out of them. Thus, the efficiency of the power unit has reached a new level with the advent of DOHC.

Gas distribution system OHV

Such a gas distribution mechanism was designed back in the 20s of the last century. At the very beginning of the article, we have already touched on it a little. Here the camshaft is in the cylinder block, and the valves are set in motion through the rocker arms and rocker (rocker arms). The main advantage of this system over the upper shaft is the absence of piles in the head, such as the camshaft and its bed. This is especially true for V-shaped engines, since their width is significantly reduced. The disadvantages have already been discussed - limited revs, high inertia, low torque and power. In addition, such a system practically eliminates the use of 4 valves in one cylinder, except in very expensive solutions. Of course, this is implemented in Nascar cars, but not in a production car.

Conclusion

It is worth remembering that these are far from all types of gas distribution mechanisms. For example, in engines whose revolutions exceed 9000 rpm, it is almost impossible to use springs under the valve plates, since they must be very rigid, and this is a loss. So, in such engines, one camshaft opens the valve, and the second closes it. This system allows you to work without "valve stuck" at speeds exceeding 14,000 crankshaft revolutions per minute. Basically, the scope of this technology is limited to motorcycles, the power of which exceeds 120 horsepower.